About the carbon residue

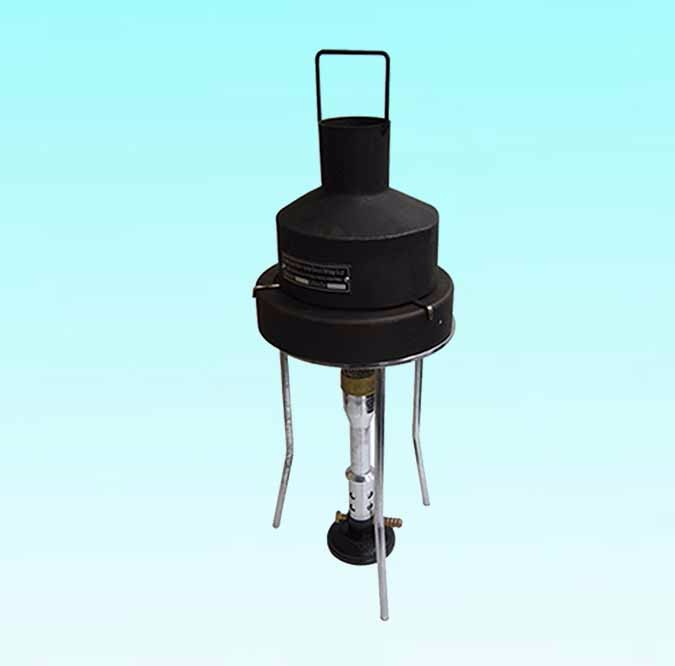

There are many methods for detecting carbon residue, such as electric furnace residual carbon, micro carbon residue, and Conradson Carbon Residue. The following is a description of Conradson Carbon Residue method.

The carbon residue of the oil refers to the oil placed on the side of the charcoal side, heated and evaporated under the test conditions without air, and the remaining black residue in the instrument after the exhausted steam is burned. It is carbon residue, expressed in mass percent.

Residual carbon is an indicator of the degree of inspection and refining in the specification of lubricating oil, and has great significance for guiding production. The amount of carbon residue in the lubricating oil is related to the chemical composition and degree of refining of the lubricating oil. A lubricating oil made of a crude oil containing a large amount of colloidal substance has a large amount of residual carbon. When the fraction of the same crude oil is refined and refined by different methods, the amount of carbon residue in the product is different, the refining depth is large, the content of heavy aromatic hydrocarbons and colloids in the product is reduced, and the residual carbon of the product is also reduced.

The main substances that form carbon residue in lubricating oil are colloidal, asphaltene and polycyclic aromatic hydrocarbons. They are easily decomposed and condensed by residual heat under the condition of insufficient air. Therefore, the residual carbon is used in lubricating oil. Used in production to check the degree of refining.

In the production, not only the products with specifications of the carbon residue project are measured, but also the semi-finished products in the refining are often inspected. In addition, the coking material was also measured for carbon residue to estimate coke production. The more carbon residue, the higher the coke production.

In the early days, carbon residue was used as an indicator to determine the tendency of lubricating oil to form in the engine. However, it has been experimentally proved that there is no corresponding relationship between the tendency to form carbon deposits and the residual carbon of lubricating oil.

The tendency to coke in a reciprocating steam engine can be approximated by the residual carbon of the cylinder oil. Because cylinder oil may be thermally decomposed when used in a steam engine, such as more carbon residue, the tendency to coke is greater.

At present, in the petroleum product specifications, in addition to a part of the lubricating oil specified in the residual carbon, in the light diesel oil specification, there is a 10% steam residue carbon residue.